In the realm of manufacturing and design, precision is paramount. Achieving the perfect cut or engraving can make all the difference between a successful product and a flawed one.

This is where CNC laser cutting shines, a technology that has revolutionised the industry. Let’s delve into the intricate world of CNC laser cutting and uncover the secrets behind its unmatched precision.

Understanding CNC Laser Cutting

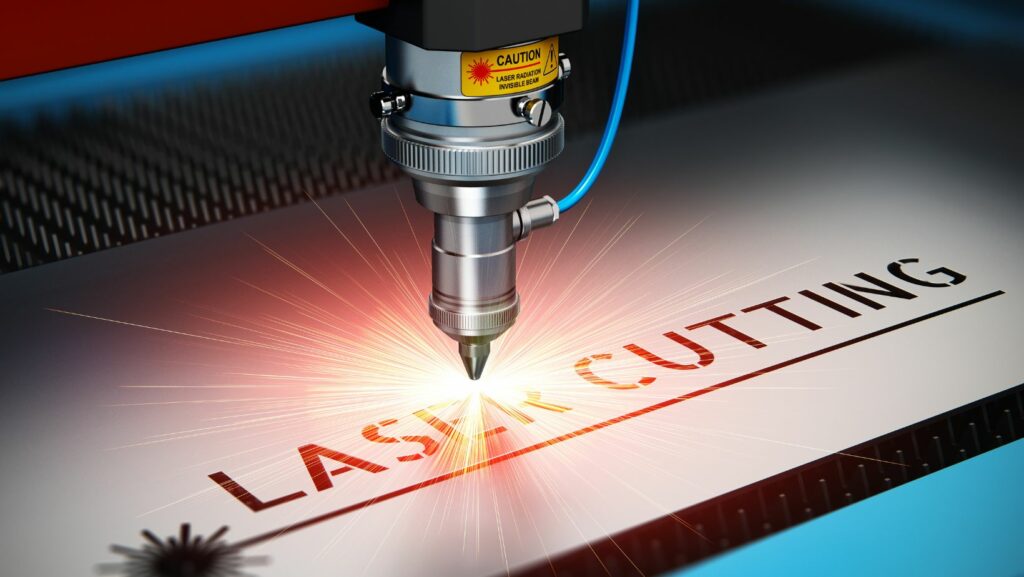

CNC laser cutting stands for Computer Numerical Control laser cutting, a process that employs a high-powered laser beam guided by a computer to cut or engrave materials with exceptional accuracy.

This technology is widely used in various industries, including automotive, aerospace, and electronics, to create intricate designs and components with precise dimensions.

The Advantages of CNC Laser Cutting

One of the most significant benefits of CNC laser cutting is its ability to produce clean, smooth edges with minimal material wastage.

Unlike traditional cutting methods, the laser beam does not wear out, ensuring consistent quality throughout the production process. Additionally, the precision of CNC laser cutting allows for the creation of complex shapes and designs that would be impossible or time-consuming to achieve with conventional methods.

The Role of Software in Precision

The precision of CNC laser cutting is largely dependent on the software used to control the machine. Advanced software enables the laser to follow intricate paths with pinpoint accuracy, ensuring that each cut is exactly as intended.

This level of control is essential for producing components with tight tolerances and complex geometries.

Materials and Applications

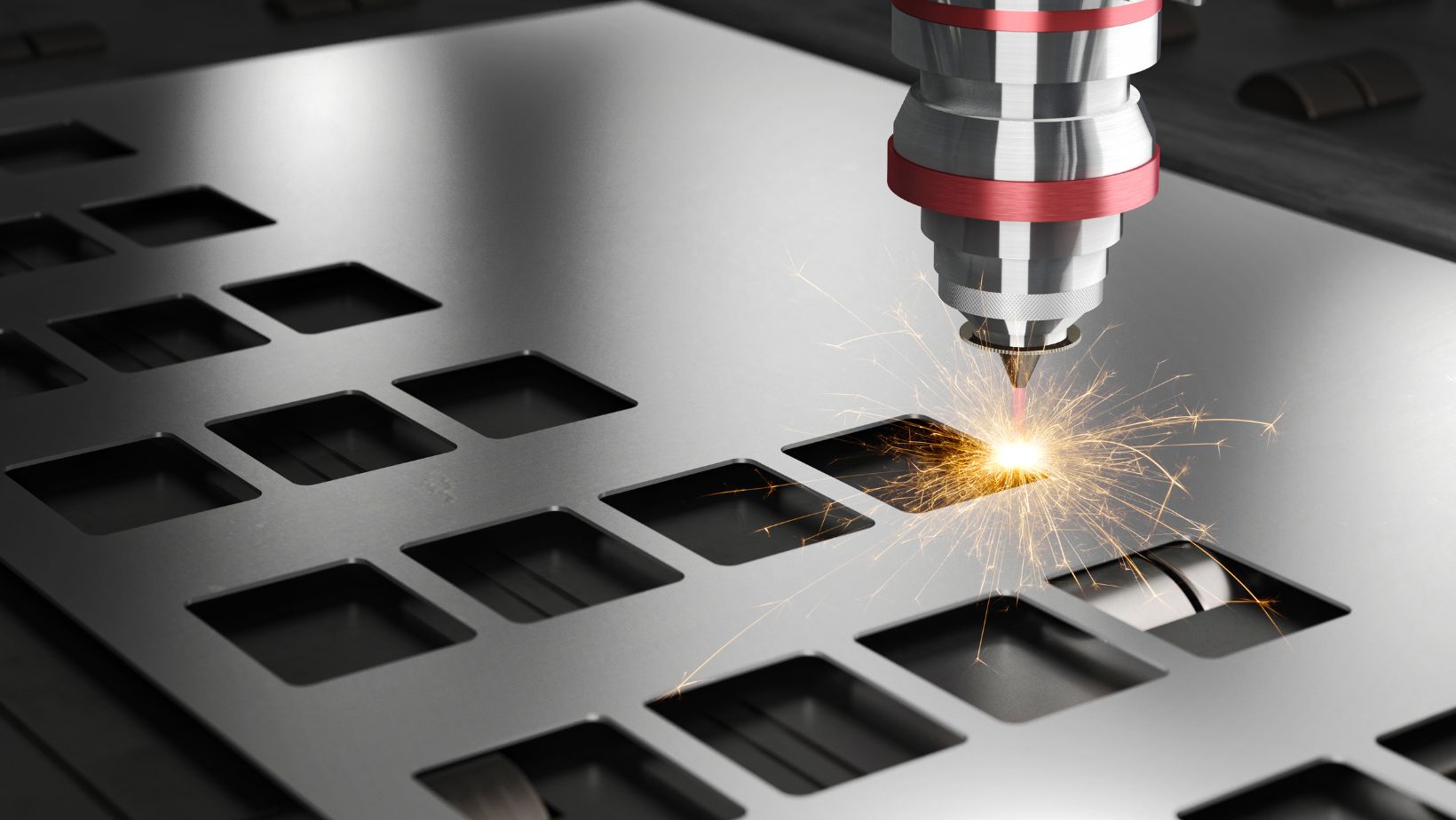

CNC laser cutting is versatile and can be used on a wide range of materials, including metals, plastics, wood, and glass.

This flexibility makes it a popular choice for various applications, from creating intricate jewellery designs to producing precise aerospace components.

The ability to cut through different materials with the same machine adds to the efficiency and cost-effectiveness of the process.

The Future of CNC Laser Cutting

As technology advances, the capabilities of CNC laser cutting continue to expand. Innovations in laser power and control software are pushing the boundaries of what can be achieved, allowing for even greater precision and speed.

The future of CNC laser cutting looks promising, with potential applications in emerging fields such as microfabrication and biomedical engineering.

Safety and Environmental Considerations

Safety is a crucial aspect of CNC laser cutting. Operators must be trained to handle the equipment safely and adhere to strict safety protocols to prevent accidents.

Additionally, the process is relatively environmentally friendly, as it produces minimal waste and can be used to cut recyclable materials.

In a nutshell, CNC Laser Cutting is a game changer

CNC laser cutting is a powerful tool in the world of manufacturing, offering unmatched precision and versatility.

Whether you’re involved in the automotive industry, electronics, or any field that requires precise cutting and engraving, CNC laser cutting is a technology worth exploring.

For those looking to delve deeper into the world of CNC technology, exploring CNC routing services can provide additional insights and opportunities for precision manufacturing.